Wire strippers are one of the most indispensable tools for anyone working with electrical wiring, from seasoned electricians to DIY enthusiasts. Whether you’re preparing wires for a home project or handling complex electrical systems, wire strippers provide precision and efficiency when removing insulation from electrical wires. In this guide, we’ll cover everything you need to know about wire strippers, from their types and uses to essential tips for getting the best results. We’ll also discuss when it’s time to call a professional.

What Are Wire Strippers?

Wire strippers are handheld tools designed to remove the plastic or rubber insulation around electrical wires, exposing the metal core beneath. This process is essential for making electrical connections, splicing wires, or attaching terminals. The best wire strippers allow you to perform this task cleanly and safely without damaging the wire’s conductive core.

When Wire Strippers Come in Handy

Wire strippers are incredibly versatile tools that come in handy for various applications, making them an essential part of any toolkit. Here are some scenarios where wire strippers are indispensable:

- Home Electrical Repairs

From replacing an old outlet to installing a ceiling fan, wire strippers are essential for exposing the wire ends needed to make electrical connections. - Automotive Repairs and Upgrades

Working on car wiring, such as installing a new sound system or repairing headlights, requires precise stripping to ensure secure connections without damaging the wire. - DIY Electronics Projects

Hobbyists and makers rely on wire strippers when building custom circuits or crafting gadgets. The precise cuts help in maintaining the integrity of the wiring and ensuring smooth operation. - Industrial and Commercial Applications

Electricians working in factories or commercial buildings use wire strippers for high-capacity wiring systems, ensuring clean cuts for quick and efficient installations. - Network and Telecommunication Work

Setting up Ethernet or phone cables demands precision, which is where wire strippers shine by cleanly removing the outer jacket and exposing internal wires without nicking them. - Craft Projects Involving Wire

For jewelry making or other artistic endeavors that use wire, stripping off insulation can help achieve the desired effect while maintaining flexibility in design.

Key Features of Wire Strippers

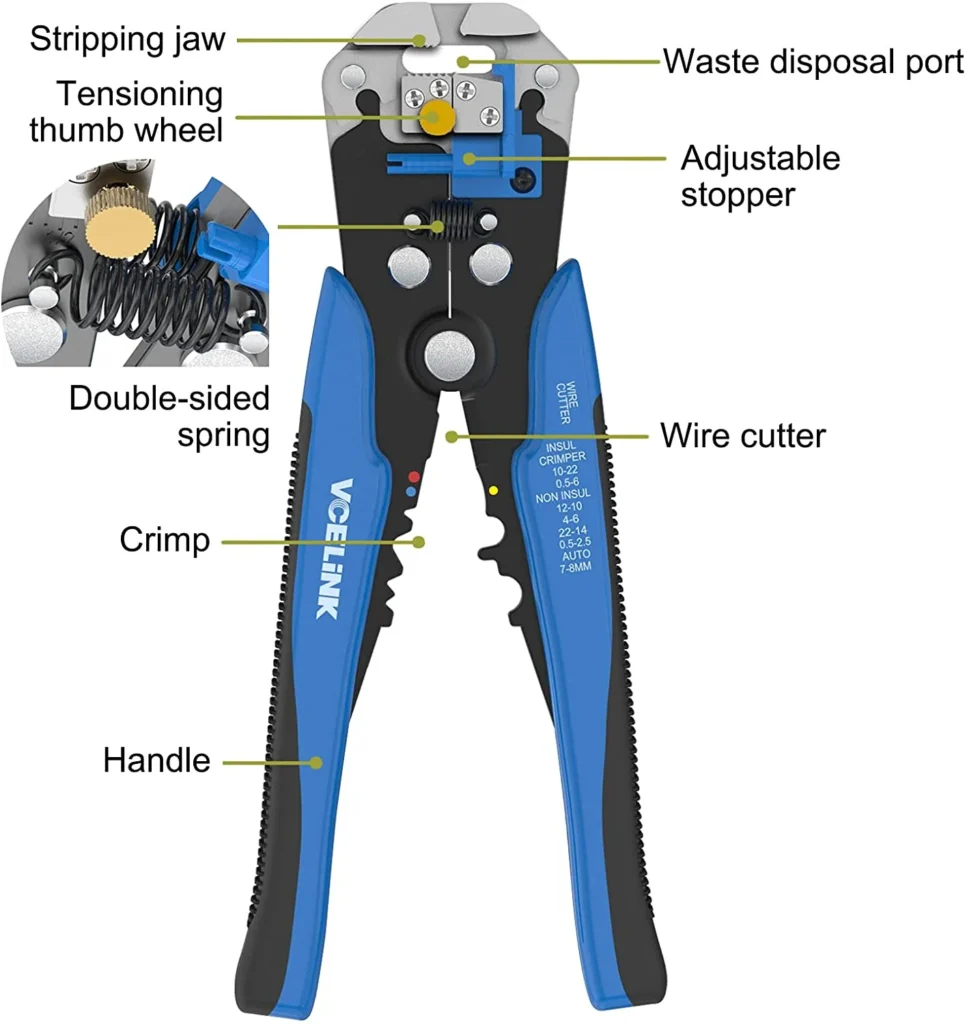

- Cutting Blades: Many wire strippers include sharp edges for trimming wires to the desired length.

- Gauge-Specific Slots: Notches or adjustable slots on the tool accommodate different wire gauges, ensuring precise stripping.

- Ergonomic Grips: Designed for comfort and long-term use, many models feature cushioned handles.

- Versatility: Some wire strippers offer additional functionalities, such as crimping connectors, bending wires, or cutting screws.

Types of Wire Strippers

Understanding the types of wire strippers available will help you choose the right tool for your project.

1. Manual Wire Strippers

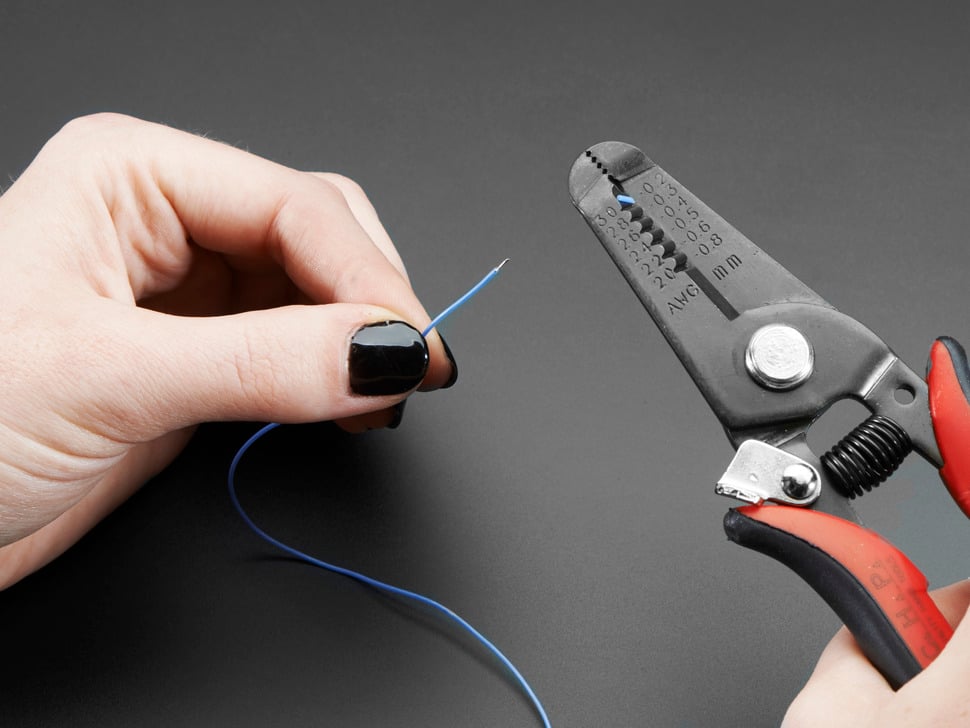

Manual wire strippers require the user to align the wire in the correct slot, close the tool around the insulation, and pull. These are straightforward and affordable, making them ideal for occasional users.

2. Automatic Wire Strippers

Automatic wire strippers grip the wire and strip the insulation in a single motion. They are fast and efficient, particularly for stripping multiple wires or dealing with thick insulation.

3. Self-Adjusting Wire Strippers

These tools automatically adjust to fit various wire sizes, eliminating the need to match the wire gauge manually. Self-adjusting wire strippers are versatile and save time, especially in large-scale projects.

Maintaining Your Wire Strippers for Longevity

Like any tool, wire strippers require regular maintenance to ensure optimal performance and a long lifespan. Proper care not only enhances efficiency but also ensures safety during use. Here are some maintenance tips for your wire strippers:

- Clean After Every Use

Residue from insulation and dust can accumulate in the stripping slots and blades. Wipe down the tool with a clean cloth after each use to prevent buildup. For stubborn debris, use a small brush or compressed air. - Check for Blade Sharpness

Dull blades can damage wires or make stripping difficult. If you notice reduced performance, sharpen the blades or replace them if necessary. Some advanced models come with replaceable blades for easy maintenance. - Lubricate Moving Parts

Apply a small amount of lubricant to the pivot point of the tool to keep it operating smoothly. This prevents stiffness and ensures the tool opens and closes with ease. - Inspect for Damage

Regularly check the tool for any signs of wear or damage, such as cracks in the handle or bent components. Replace the tool if it shows significant damage to avoid accidents or inefficient performance. - Store Properly

Keep your wire strippers in a dry, clean location to prevent rust or corrosion. Using a dedicated tool pouch or box can protect them from accidental impacts or exposure to moisture. - Avoid Overuse or Misuse

Use your wire strippers only for their intended purpose. Cutting screws or nails with the blades can dull them prematurely or cause permanent damage.

By incorporating regular maintenance and using wire strippers appropriately, you can extend their functionality and get the most out of this indispensable tool.

Tips and Tricks for Using Wire Strippers Effectively

Using wire strippers seems straightforward, but these tips and tricks can ensure better results and help you avoid damaging your wires.

1. Choose the Right Tool

Ensure your wire stripper matches the gauge of the wire you’re working with. Using an improper gauge slot can nick or weaken the wire, leading to potential failure.

2. Inspect the Wire

Before stripping, check the wire’s insulation for damage or wear. Stripping a compromised wire could lead to inaccurate cuts or unsafe connections.

3. Secure the Wire

Hold the wire firmly with one hand while operating the wire stripper. This minimizes movement and ensures a cleaner cut.

4. Practice Consistency

When stripping multiple wires, aim to expose the same length of wire each time. This ensures uniform connections and a professional appearance.

5. Avoid Excessive Force

Don’t apply more pressure than necessary when gripping the wire stripper. Excess force can damage the conductor beneath the insulation.

6. Clean Your Tool

Dust and debris can accumulate on your wire stripper, affecting its performance. Regularly clean the blades and slots to maintain precision.

When to Call a Professional

While wire strippers make electrical work accessible to many, certain situations require the expertise of a licensed electrician. Consider calling a professional if:

- Complex Systems Are Involved: If you’re dealing with a home’s main electrical panel, HVAC system, or any high-voltage wiring, leave the work to a professional.

- You Notice Damage or Corrosion: Exposed or damaged wires can be dangerous. An expert can assess and repair them safely.

- Permits Are Needed: Some electrical jobs require permits or must meet specific codes. A professional can ensure compliance.

- You’re Unsure of the Scope: If you’re unfamiliar with electrical systems or the task feels overwhelming, it’s better to be safe than sorry.

Wire Strippers and Safety: What to Know Before You Start

Working with electrical wires requires caution, and wire strippers are no exception. Keep these safety considerations in mind:

- Turn Off Power: Before stripping wires, ensure the power to the circuit is turned off to avoid electrical shocks.

- Use Insulated Tools: Look for wire strippers with insulated handles to protect against accidental contact with live wires.

- Work in a Well-Lit Area: Good visibility reduces the risk of mistakes or injuries.

- Test the Connection: After stripping and connecting wires, use a multimeter to verify the connection is secure and functioning correctly.

Expanding Your Knowledge: Accessories for Wire Stripping

To get the most out of your wire strippers, consider pairing them with additional tools and accessories:

- Wire Crimpers: For attaching connectors or terminals after stripping.

- Heat Shrink Tubing: Provides insulation and protection for newly stripped wires.

- Cable Testers: Ensure that your stripped and connected wires are functioning properly.

Elevate Your Projects with Wire Strippers

Wire strippers are indispensable tools that simplify the process of preparing electrical wires for connections. Whether you’re tackling a home project, repairing electronics, or diving into automotive wiring, the right wire stripper can make all the difference. By choosing the right type, following best practices, and knowing when to call a professional, you’ll ensure safe and successful results every time.

For anyone venturing into the world of electrical projects, understanding the role of wire strippers is an essential step. Let this guide be your starting point as you master the art of wire preparation.