Leading flooring manufacturer Amtico have a variety of highly technical programs and machines at their disposal which they have developed over years of working at the top of the flooring industry. However, unlike some other leading businesses, when the COVID-19 pandemic brought life as we knew it to a standstill back in March, Amtico were able to use their technology in a different way.

At their large manufacturing facility in Coventry, England, Amtico usually produces a wide range of vinyl flooring. This flooring is perfect for your home with its highly durable and water-resistant surface, making their vinyl an ideal flooring option for your bathroom, kitchen and other rooms in your home. Amtico produce their vinyl with multiple layers, which is one reason why it is so durable. Their luxury vinyl tile, which is sometimes referred to as LVT, is made by heat-compressing several material layers. This includes multiple performance layers, along with an aesthetic layer and backing layers.

With COVID-19 cases rising and a lockdown in effect across England, Amtico looked at their manufacturing capability and asked if there was something they could do to help. As more people were admitted to hospital with COVID-19, it was becoming clear that the UK was suffering from a shortage of personal protective equipment (PPE). Amtico was able to quickly adapt their manufacturing capabilities to provide PPE to help the shortage.

Using the materials and machinery which usually produce LVT, Amtico worked with schools around the UK to assemble and produce PPE for frontline key workers. Face shields played a crucial part in protecting those who were coming into contact with people suffering from COVID-19.

Amtico assembled people from their technical department, cutting specialists and CAD team to modify the design of a face shield headband in just a few hours. CAD plays a key role in Amtico’s ability to deliver flooring which is right for their client’s needs, as they use the technology to design flooring patterns for a variety of commercial projects.

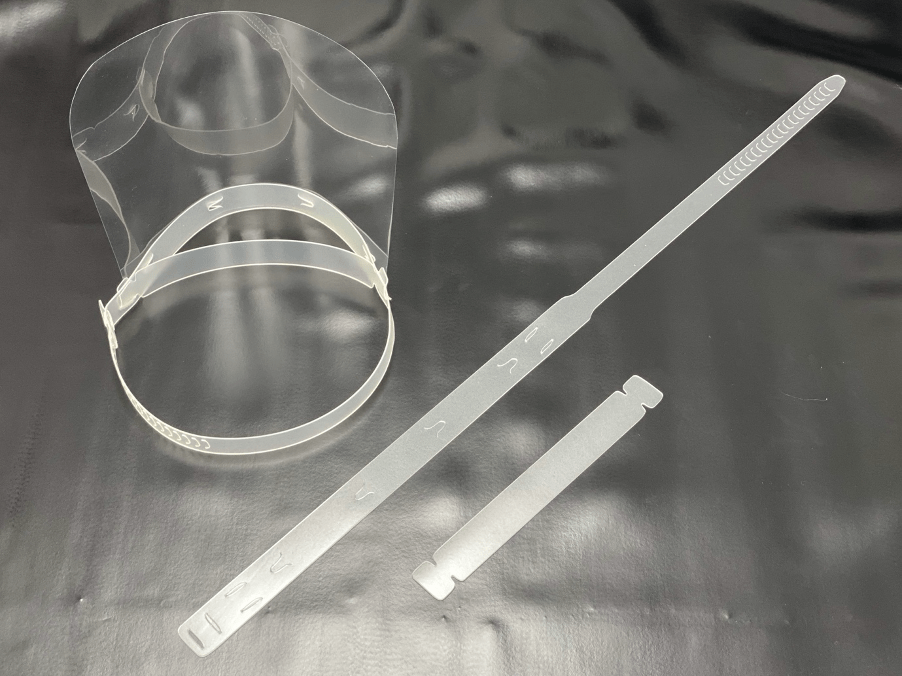

The original 3D printed design for the face shields had been created by a school in the UK and was made of three separate components. With Amtico’s help, the most complex part of the design was refined, and the new design was more efficient and could be produced quicker. The new design was made up of only two separate components which allowed it to be more structurally sound along with reducing waste and being more secure. Amtico also created a new composition of its flooring material specifically for the headbands.

Amtico’s Head of Technical, Gary Wilson, explained: “We used a material modified from the 1mm wear layer used in our Signature LVT product, which is chemically inert and made with a phthalate-free plasticiser. This is extremely flexible, durable, and it is easy to cut, so we were able to produce the headband with tolerances that allow a secure, comfortable fit.”

By using their technology in this way, Amtico worked with Merchant Taylors’ School in Hertfordshire, England, to increase the production of face shields from 650 to 4,500 per week. In early April a sample of the face shields were taken to Watford General Hospital where an ICU surgeon approved the design and placed an order for 2,000 units which Amtico produced free of charge.

Since then, Amtico has produced PPE which has supported over 70,000 key workers and have delivered flat-pack face shields to NHS hospitals, care home, doctors’ surgeries and others. Thanks to the materials Amtico used, the face shields have even proven strong enough to be sanitised and re-used.

Jonathan Duck, CEO at Amtico, said: “I’m proud of the way Amtico, as a company rises to new challenges. Members of our CAD, cutting and material development teams listened carefully to feedback from the NHS to make sure the headband was not only functional but comfortable. We were able to draw on our technical expertise, modifying the design for maximum efficiency, scaling up production and helping local schools support the NHS and other key workers.”

This example of Amtico looking at their internal technology and materials, working out how they can help, then putting the time and effort into delivering a solution which benefited others was seen from other companies during the height of the pandemic and lockdown.